Products

By Team

Sales

Multithread effectively and personalize outreach to convert deals faster

Social Media Marketing

Elevate social presence and drive business growth from social media

RevOps

Identify and prioritize high-intent leads, and improve sales effectiveness

Events & Field Marketing

Find and connect with ICP attendees, and improve event outcomes

Resources

GE Additive

What Does GE Additive Do?

GE Additive, part of GE Aerospace, is a global leader in additive manufacturing, also known as 3D printing. The company offers a comprehensive portfolio of solutions including advanced 3D printing machines (Direct Metal Laser Melting, Electron Beam Melting, Binder Jet), a wide range of metal powders, and expert engineering and consulting services. GE Additive aims to transform businesses by improving product design, accelerating manufacturing processes, and optimizing supply chains. They serve diverse industries such as aerospace, healthcare, automotive, dental, and energy, helping them produce complex parts with enhanced performance and reduced costs. Their commitment to innovation drives the industrialization of additive manufacturing, making it a reliable and mainstream production method.

Where Is GE Additive's Headquarters?

HQ Function

The Munich facility serves as a key leadership base, a Customer Experience Center for customer collaboration, application development, training, and showcasing GE Additive's latest technologies.

Notable Features:

State-of-the-art facility housing a wide range of GE Additive machines, collaborative workspaces for engineers and customers, and advanced metrology and testing labs.

Work Culture:

Fosters innovation, customer-centric problem solving, and collaboration. The environment encourages continuous learning and the adoption of cutting-edge manufacturing technologies.

HQ Significance:

Munich is a major European industrial and technology hub, providing proximity to key customers, talent, and research institutions, enabling GE Additive to drive adoption of additive manufacturing in the region.

Values Reflected in HQ: Reflects GE Additive's commitment to innovation, customer partnership, technological leadership, and advancing the field of additive manufacturing.

Location:

GE Additive supports its global customer base through a network of manufacturing sites, research and development centers, customer experience hubs, and sales and service offices across North America, Europe, and Asia. Key functions supported globally include machine manufacturing (DMLM, EBM, Binder Jet), metal powder production, application engineering, customer training and support, R&D in new materials and processes, and strategic consulting to help industries adopt and scale additive manufacturing.

Street Address:

Lichtenbergstraße 8

City:

Garching b. München

State/Province:

Bavaria

Country:

Germany

Where Else Does GE Additive Operate Around the World?

West Chester, Ohio, USA

Address: 9992 International Blvd, West Chester Township, OH 45246, USA (Additive Technology Center)

Serves as a key North American hub for additive innovation, production, and supports GE Aerospace's internal additive manufacturing needs.

Lichtenfels, Bavaria, Germany

Address: An der Zeil 8, 96215 Lichtenfels, Germany

Center of excellence for DMLM technology, R&D, machine production, and serving the European market for metal additive manufacturing.

Mölndal, Västra Götaland, Sweden

Address: Krokslätts Fabriker 27A, 431 37 Mölndal, Sweden

Global center for EBM technology development, machine manufacturing, and powder recovery systems, with a strong focus on orthopedic and aerospace applications.

Saint-Eustache, Quebec, Canada

Address: 3700 Rue F.-X.-Tessier, Saint-Eustache, QC J7R 0G7, Canada

Key global supplier of premium powders (titanium, nickel, aluminum alloys) for the additive manufacturing industry, supporting GE Additive's ecosystem and the broader market.

Buying Intent Signals for GE Additive

Highperformr Signals uncover buying intent and give you clear insights to target the right accounts at the right time — helping your sales, marketing, and GTM teams close more deals, faster.

Who's Leading GE Additive? Meet the Executive Team

As of April 2025, GE Additive' leadership includes:

Who's Investing in GE Additive?

GE Additive has been backed by several prominent investors over the years, including:

What Leadership Changes Has GE Additive Seen Recently?

In the past year, GE Additive has seen a key leadership transition with the appointment of a new CEO, Alexander Schmitz, highlighting the company's ongoing commitment to driving growth and innovation in the additive manufacturing sector.

Departures

New Appointments:

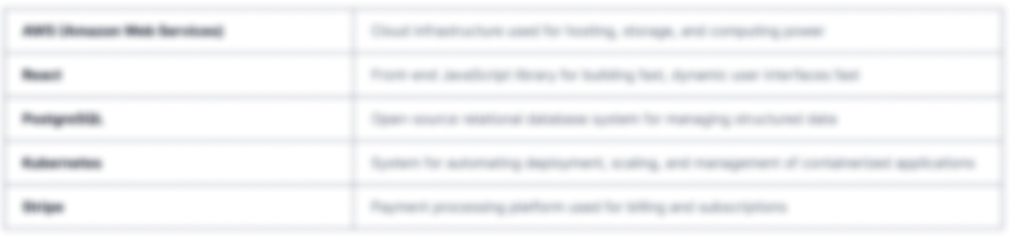

What Technology (Tech Stack) Is Used byGE Additive?

Discover the tools GE Additive uses. Highperformr reveals the technologies powering your target accounts — helping your sales, marketing, and GTM teams prioritize smarter and close faster.

GE Additive Email Formats and Examples

GE Additive, as part of General Electric, primarily utilizes GE's corporate email format. The most common and widely used format is [first].[last]@ge.com. While variations might exist for specific roles or legacy systems, this pattern has a high success rate for reaching GE employees.

[first].[last]@ge.com

Format

jane.doe@ge.com

Example

90%

Success rate

What's the Latest News About GE Additive?

GE Newsroom • January 8, 2024

GE Additive Appoints Alexander Schmitz as CEO

GE Additive announced the appointment of Alexander Schmitz as its new Chief Executive Officer. Schmitz, who will be based in Munich, Germany, took leadership of the company effective January 2024, succeeding Riccardo Procacci....more

TCT Magazine • November 15, 2023

GE Additive & Toolcraft AG to qualify aluminum alloy for aerospace applications on GE Additive Concept Laser M2

GE Additive collaborated with Toolcraft AG to qualify an aluminum alloy (A20X) for aerospace applications using the GE Additive Concept Laser M2 Series 5 machine, aiming to enhance performance and lightweighting in aerospace components....more

GE Additive Press • November 7, 2023

GE Additive Showcases Latest Innovations for Industrializing Additive Manufacturing at Formnext 2023

At Formnext 2023, GE Additive presented its latest advancements in machines, materials, software, and services, emphasizing its focus on driving the industrialization and series production capabilities of additive manufacturing across various sectors....more

Highperformr's free tools for company research

Explore Employees by Region or Country

See where a company’s workforce is located, by country or region.

View Funding Details

View past and recent funding rounds with amounts and investors.

Understand Revenue Insights

Understand company revenue estimates and financial scale.

Track Active Job Openings

Track active roles and hiring trends to spot growth signals.

Review Product and Offerings

Discover what a company offers—products, platforms, and solutions.

Get SIC or NAICS Codes

Get the company’s official SIC and NAICS classifications.

Analyze Website Traffic Trends

Analyze visitor volume, engagement, and top traffic sources.

Discover Social Profiles and Engagement

Explore LinkedIn, Twitter, and other active social profiles.

Identify Top Competitors

Identify top competitors based on similar business traits.

Research and Discover Companies with Highperformr — Smarter, Faster

Explore companies in depth — from the tech they use to recent funding, hiring trends, and buyer signals — all in one powerful view.

Highperformr AI helps you surface the right accounts and enrich your CRM with verified company and contact insights, so your teams can prioritize and engage faster.

- Track intent signals to find buyers who are actively in-market

- Enrich contacts and companies instantly, no need to switch tools

- Automate workflows to stay ahead of every change

- Connect your CRM & tools for seamless data sync and activation

Thousands of companies, including GE Additive, are just a search away.

.png)

.png)